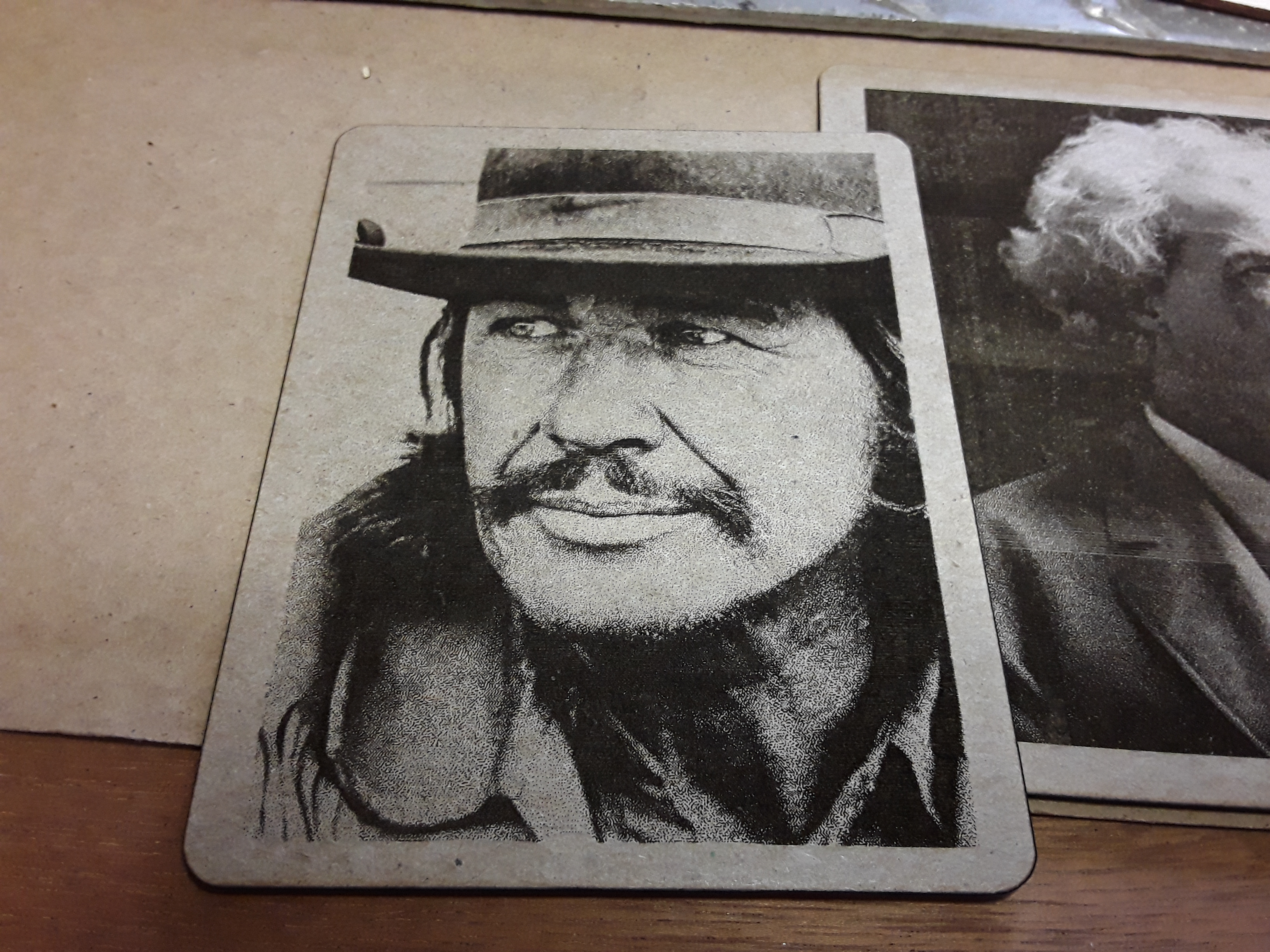

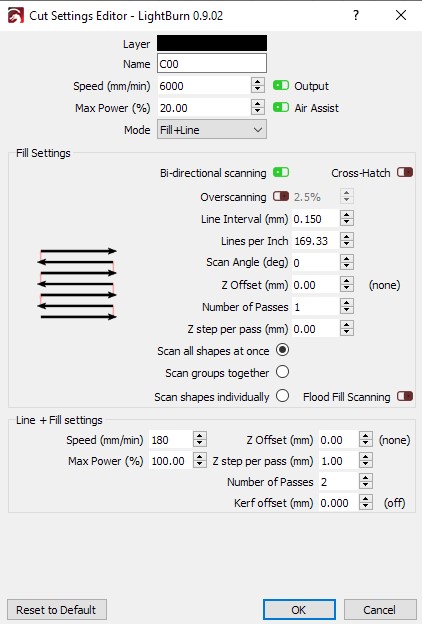

Since then I’ve come to prefer Grbl for my stable of machines (I don’t currently have any set up with Marlin…) and discovered Lightburn. TBH I don’t remember much about all the testing and discussion we did (probably an age thing…I’d have to re-read the thread) and don’t know whether those mods actually made it into the current Marlin build (Ryan and Jeff should know…). It’s confusing but, though similarly named, these are NOT the same program. In that same thread, I also discovered Victor’s ImageToGcode program, which seemed to give me better results at the time than the Image2Gcode program I had been using… and which you are using now. Here is a lengthy thread from a year or two ago, that will give you some history behind the firmware mods (that I think you’ve applied) that had to be applied to get good engravings from the later versions of Marlin. I hope you find the pleasure in your development with your laser.Hate to tell you… but none of this stuff is “a piece of cake” Choose an image that is high in contrast and does not contain too much background “noise”. otherwise the dots just lie on top of each other and give a wrong (too dark) image. Therefore the DPI setting should probably be between 200 and 275 max. It is also important to mention that your “distance of the dots” is physically limited to the size of your laser. I would recommend that you start with pictures that are not too small, it makes things easier in the beginning. You will experiment with different materials and before and after finishes. It sounds banal, but only practice, practice and practice can do it. The large lasers can sometimes only engrave in the very light tones if you set the speed up a lot.

With my 40 Watt laser I engrave with about 8-10%, i.e. The powerful machines are usually better suited for cutting material and not so much for engraving, but of course it can still give good results, it just requires even more finesse with everything around your laser. You should probably be aware that your laser is very powerful and which requires a very finely adjusted laser beam to give good engraving results.

I do not agree with you, your power test shows quite fine variations.

0 kommentar(er)

0 kommentar(er)